Spindle Repair

For our original spindles, we are available for regular repair requests. Here we explain the repair process and key points that we consider important.

This procedure has been passed down over many years at Yamada Koki and has been faithfully carried on at Irino Kiko with its exceptional techniques, so you can have peace of mind.

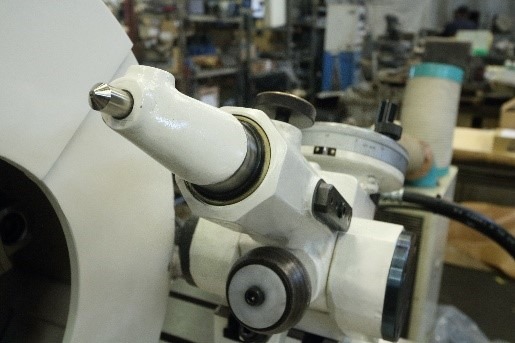

Procedure 1: Initial Condition Check of the Spindle

1. Check the bearing rotation condition and assess any damage to the bearings.

2. Pay special attention to the condition of the spindle’s inner diameter (MT taper).

→ At this stage, we roughly determine if the spindle shaft can be reused.

3. Check the condition of the spindle mounting surface.

→ The condition of this mounting surface affects precision during actual grinding.

Procedure 2: Disassembly of the Spindle

1. Carefully disassemble spindle components (spindle shaft, bearing spacers) without causing any damage.

2. Examine bearing damage and analyze its causes.

(a) Check for flaking → Possible causes include improper assembly, spindle deflection, misalignment, or housing precision issues.

(b) Check for seizure → Possible causes include poor lubrication, foreign object intrusion, or rust.

(c) Check for damage → Possible causes include abnormal load or poor lubrication.

(d) Check for indentations → Possible cause is intrusion of foreign substances such as metal powder.

(e) Check for abnormal wear → Possible cause is minor oscillations during transport.

We carefully examine the state and damage of the bearings, determine the probable cause, and devise measures for reassembly.

Procedure 3: Spindle Restoration and Assembly

1. Thoroughly clean the bearings, removing rust-prevention oil and contaminants from inside the bearings.

2. Manually rotate the bearings slowly, ensuring no rotational vibration is felt during cleaning.

3. Apply the optimal amount of grease (the amount of grease significantly affects bearing lifespan).

During assembly, we emphasize minimizing stress on the bearings. We believe this approach contributes to the long lifespan of our spindles.

Procedure 4: Verification by Rotation Operation

1. Perform rotation to bring out the bearing’s inherent characteristics.

2. During rotation, check the following items:

(a) Temperature increase

(b) Continuous real-time analysis and monitoring of the frequency of the inner and outer bearing rings, rolling elements, and retainer using an accelerometer

(c) Confirmation of spindle stable saturation

Procedure 5: Accuracy Check

We check the runout accuracy of the rotating bearing part twice: after spindle assembly and after verifying the rotation operation.

Procedure 6: Preparation for Return

A report on the repair details will be attached when returning the spindle.

If you have any questions about our spindles or bearings, please feel free to contact the technical staff in our Manufacturing Department, Spindle Division.

Other Repairs

We also accept repairs for items such as dressers and feed handles. For machine malfunctions or issues, please do not hesitate to contact us.